OUR PRODUCTS

Zircom Sintering Furnace (for Zirconia Materials)

Zircom Standard

Req 220V

For normal sintering time (avg7-10 hrs material). In 3 ceramic trays formation

total 50-60 single crown sintering.

Zircom Sintering Furnace delivers delicacy and beauty to your zirconia. It features molybdenum disilicide heater that provides clean, reliable, and consistent results.

Zircom Speed

Req 220V

Forced on 90 minutes sintering material But normal sintering time (avg7-10 hrs material) available too. Customers can choose for each material scheduling time. 2 Carbon(SiC) Trays formation for 90 min fast sintering material( total 20 single crowns). Also normal sintering time (avg7-10 hrs material), In 3 ceramic trays formation total of 50-60 single crown sintering.

Zircom Sintering Furnace delivers delicacy and beauty to your zirconia. It features molybdenum disilicide heater that provides clean, reliable, and consistent results.

Zircom Sintering Furnace delivers delicacy and beauty to your zirconia. It features molybdenum disilicide heater that provides clean, reliable, and consistent results.

Zircom Plus

Req 220V

Focused on Full Arch or Long Span bridge cases for normal sintering time (avg7-10 hrs material), In 2 ceramic trays formation total of 70-90 single crown sintering, Also 2-4 full arch long span cases.

Zircom Plus Sintering Furnace delivers delicacy and beauty to your zirconia. It features molybdenum disilicide heater that provides clean, reliable, and consistent results.

KDF Zirconia Disc

Excellent, matched to KDF Zircom sintering series for both normal and fast sintering time.

KDF research team could reach the best materials results to use Zircom series .

Porcelain and Zirconia Staining / Glazing Furnace

Master Plus

Req 120V

This is not only a Porcelain oven but is also used for zirconia material’s Staining and Glazing.

The Master Plus programming system is for all materials acceptable. Fastest finishing zirconia works will be only 100min with Zircom Speed and Master Plus.

Metal Casting Cascom Series

Neo Super Cascom

Req 220V *Only for Sale in USA / South America

Focused on eliminating air bubbles from melt alloys under the microscope.

AutoCasting system with ceramic heat element system.

The Neo Super Cascom features a specialized spiral ceramic heater element which precisely melts the alloy at desired temperatures. Such precision heating eliminates overheating of the alloy and therefore minimizes porosity.

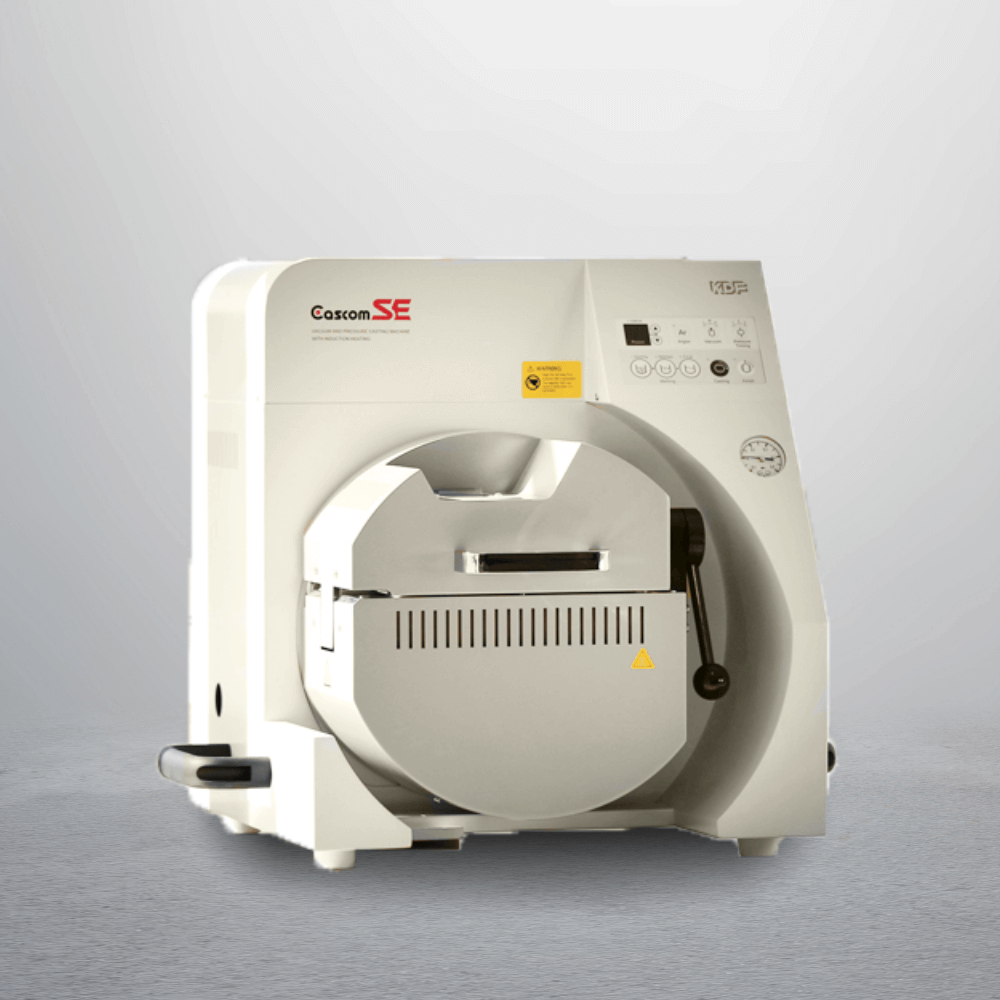

Cascom SE

Req 220V

Powerful and Fastest Casting processing (2-3 minutes result) with High-Frequency Heat System.

Also, HPC20 Chiller Coolin System (sold separately).

KDF’s newly developed Cascom SE casting machine features high-frequency induction heating of an alloy and vacuum and pressure casting.

Burnout Oven and Air Cleaner

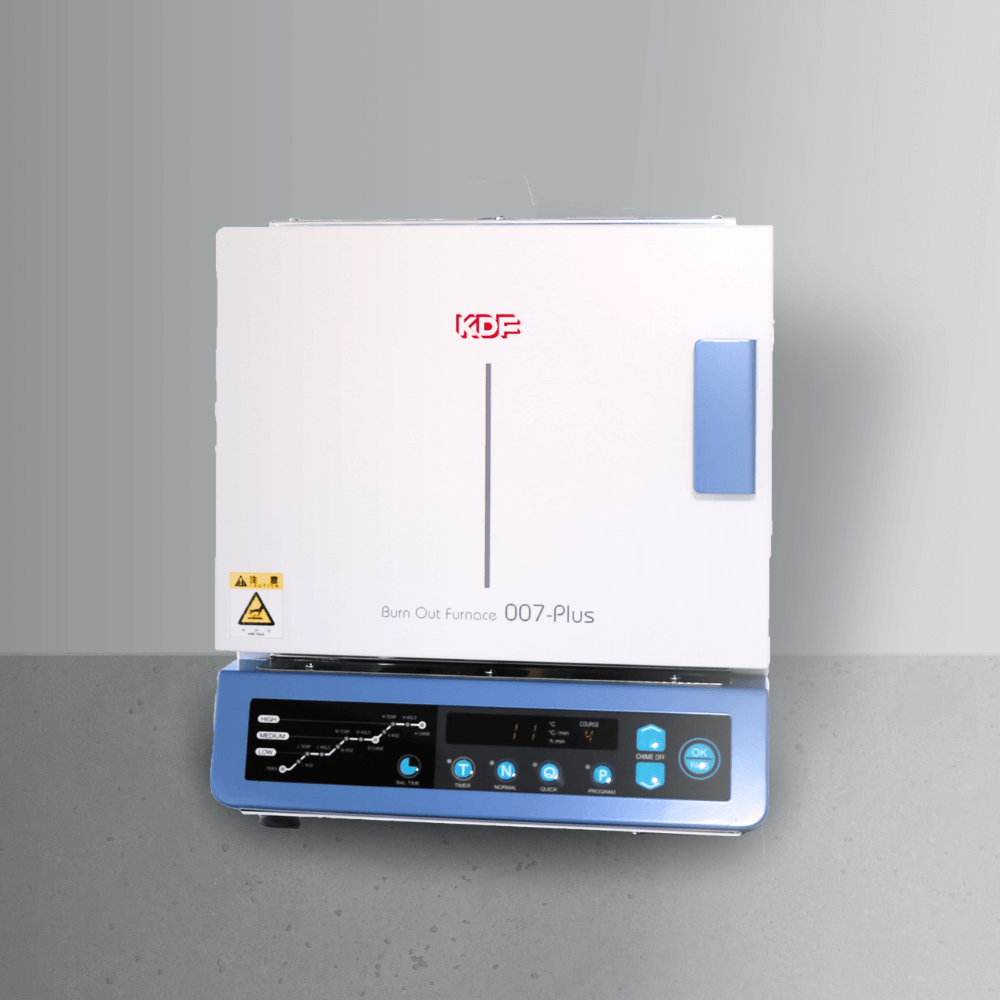

Burnout Oven 007 Plus

Req 120V

007 Plus seamless chamber structure leads to perfect and lipid burnout the waxes.

800℃ reaches in 14minuites fastest heat system. Cascom Casting machine series is the perfect match this 007 Plus.

Also, 007 Plus has Air Cleaner machine (ES71 Catalyst).

ES71 Catalyst

Air Cleaner with 007 Plus Burnout Oven

ES71 dissipates hazardous ammonia, carbon monoxide and hydrochlorides associated with burning out of casting rings.

Wax Carving Machine

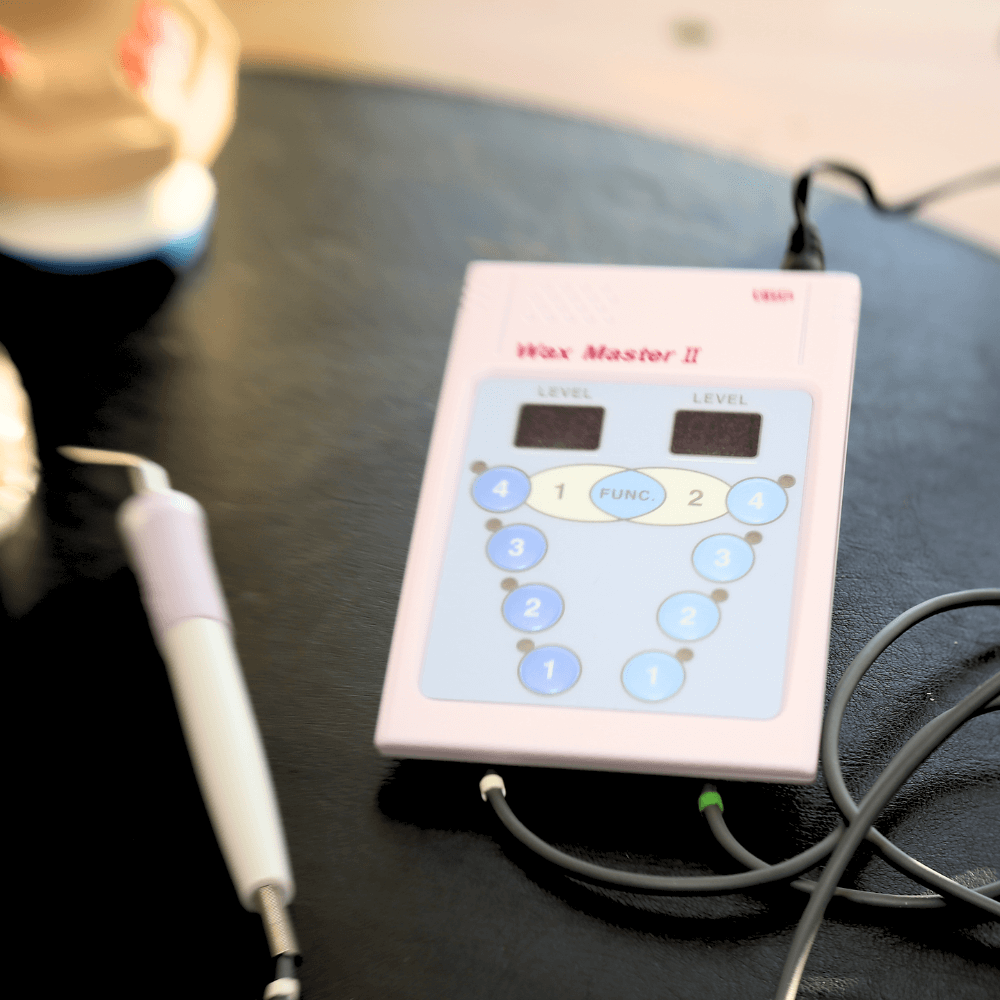

Wax Master Ⅱ

Req 120V

Five tip types fit for your sensitive waxing works.

Wax Master II features a built-in heat sensor and power switch in wax grip. Temperature adjustment can be done with your fingertips, saving time and improving efficiency. Built-in microcomputer precisely regulates heat and stores 4 independent temperature settings.

CONTACT

If you would like to order parts for your machine or have questions,

please contact your dealer directly.