Zircom Sintering Furnace Series

Standard / Plus / Speed

Troubleshooting

Zircom Error 5 Heater disconnected | KDF

Zircom Error 6 Short-circuited Thermocouple or disconnected | KDF

ZIRCOM Error 4 (Lifting Table Abnormal) Troubleshooting Guide KDF

ZIRCOM Error 4 (Lifting table abnormal) no.2 / MAY 2022 UPDATED / Troubleshooting Guide KDF

Zircom Error 9,11,12 Unstable temperature, fan error | KDF

Zircom No indicate screen How to fix black screen | KDF

Zircom Stuck Table indicating Error 6 | KDF

Zircom Speed How to stack Carbon(SiC) fasting firing trays | KDF

Zircom specification changed after 2017 notification Troubleshooting Guide KDF

Zircom unstable sintering temperature| KDF

Zircom How to replace the Furnace Unit | KDF

How to set a program on Zircom Sintering Furnace

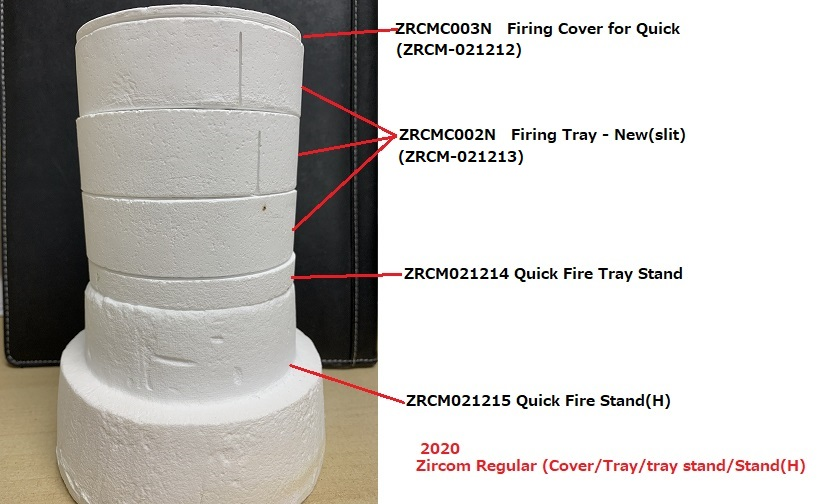

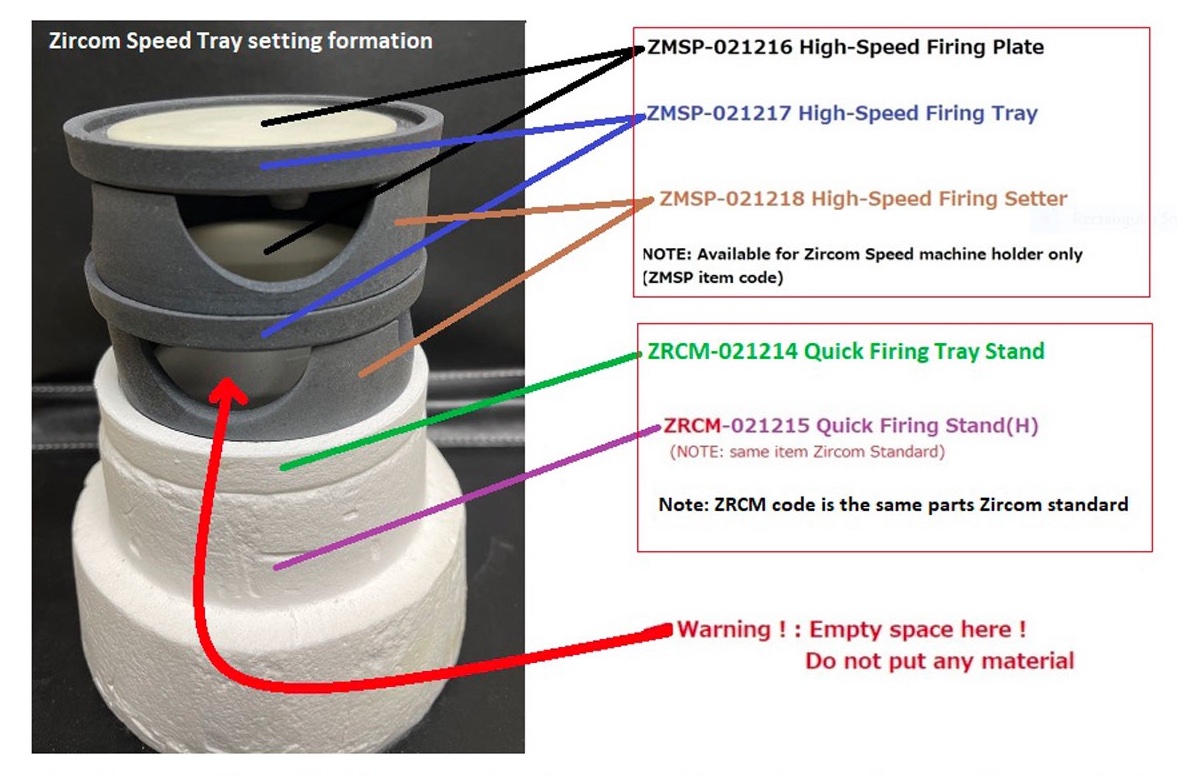

Order Parts Item Code & Name

NOTE: ZRCM-021215 Quick Firing Stand(H) is the same item Zircom Standard and Zircom Speed

NOTE: Zircom Speed has TWO types of Tray sets. One is for the Zircom Standard ceramic tray set, other is for the Zircom Speed carbon tray set.

NOTE: High-Speed Firing Tray: Silicon carbide (sic)compound form, If zirconia material touches this tray or there is no High-Speed Firing Plate, it will change the color (light YELLOW). Please do not contact the SiC tray with zirconia material. Always should be put on the High-Speed Firing Plate. Also, It can not be a cause of this tray itself to GRAY colored zirconia materials. exception: reduction firing CO concentration up 4% or please attempt other company’s zirconia material.

Mechanical Support

Power Requirements

The unit requires 220V single-phase, 20A and grounding

Unloaded Muffle Firing

When first purchasing the unit, please follow the unloaded muffle process listed below:

- Put the proper amount of beads in the firing tray, then put one or two firing trays with its cover on.

- Choose Course 0 and press [START STOP]. It takes approximately 7 hours.

How to Use:

- Powering on, then the unit displays Standby Mode

- Select the course by ▲▼

- Press [START/STOP]

How to Program:

Suppose you store a firing program on Program Course 5 as follows:

(Make sure the firing table is down)

Course Name: TEST

Step 1 Temp: 1000C Time: 40min

Step 2 Temp: 1500C Time: 60min

Step 3 Temp: 1500C Time: 120min

Step 4 Temp: 400C Time: 60min

Step 5 Temp: 300C Time: 90min

Table Position: 5.

The start temperature is 20C. It is already programmed.

- Turn on the power to go to the Standby Mode

- Press ▲▼ the button to choose course number 5

- Press [F1]

- Press ▲ to move to Course Name

- Input TEST by using [F3]&[F4] and

- Press ▼ to move back to Step 1

- Input 1000 by [F3]&[F4]

- Press to adjust time then imput 0:40 by [F3]&[F4]

- Press ▼ to move down to Step 2 then input 1500 and 1:00 by [F3]&[F4]

- Press ▼ to move down to Step 3 then input 1500 and 2:00 by [F3]&[F4]

- Press ▼ to move down to Step 4 then input 400 and 1:00 by [F3]&[F4]

- Press ▼ to move down to Step 5 then input 300 and 1:30 by [F3]&[F4]

- Press [F2] to change Setting Page (Table Position & Chme)

- Adjust Table Position to 5 by using [F3]&[F4]

- Press [F1] to return to Standby Mode

©Program will not be saved if you turn off the unit during programming.

Error Signs

- No4: Lifting Table Abnormal – Error occurs during lifting the firing

- No5: Heater Disconnection Abnormally – Heater is broken. Please replace it with a new heater

- No6: Thermocouple Error – The thermocouple is short-circulated or disconnected

- No8: Memory Error – The memory content is corrupted by the influence of noise or when the unit cannot read the memory

- No9: Excessive Rise of Temperature – The muffle temperature rises excessively

- No11: Top Cooling Fan Error – Error occurs in the top cooling fan

- No12: Under Cooling Fan Error – Error occurs in the lower cooling fan

CONTACT

If you would like to order parts for your machine or have questions,

please contact your dealer directly.